Catastrophic Failure of an OEM Glock mag

Note: The terms “base plate” and “floor plate” are used interchangeably in this article.

On US Independence Day of 2023, I dropped an OEM Glock magazine. The floor plate popped off, the spring and follower flew out, and the cartridges spewed.

I’ve seen mags from other manufacturers do that, but that was the first time I ever had it happen to me with an OEM Glock mag. I’ve been around guns since the ’70s, and around Glocks daily since the mid-90s.

Don’t get me wrong. I’m a HUGE believer in OEM—original equipment manufacturer–gear, particularly from a maker with such a solid reputation as Glock.

Glocks are the AKs of the pistol world. They simply work.

Some people try to cut budgetary corners when it comes to their life saving gear, especially magazines. But magazines are the Achilles heels of any mag-fed system. They are almost inevitably the assemblies that wear out the soonest. If your gun doesn’t feed reliably, a magazine (bent feed lips or a worn out spring) should be on your short list of suspects.

It’s OK to get low-budget aftermarket mags for practice–they might even make you better, if they force you to clear stoppages frequently–but use OEM mags for your every day carry (EDC).

Double stack, 9mm Glocks–primarily the model 19 (mid size), but also the 17 (full size), and 26 (subcompact or “baby” Glock)–are the chosen “go-to” handguns in our family.

I won’t go down the rabbit hole of listing Glock’s advantages and disadvantages and comparing them to others. As my good friend Ric Alonso says,

“The best gun for the job is the one in your hand when the stuff hits the fan.”

. . . Glocks just happen to be what we will have in ours.

We carry each Glock with the type of mag it comes with (19 mag in a model 19, 26 mag in the 26, etc) but our spare magazines are all Gock 17 mags. If you know anything about them, the reason for that will be obvious. A Glock 17 magazine is long enough to work in a Glock 17, or a Glock 19, or a Glock 26. Glock 19 mags are too short to work in a larger model 17, and Glock 26 mags will not work in a 19 or a 17.

Model 17 magazines work in every 9mm Glock we have.

Our go-to EDCs are all 9mm, not because it’s better than any other cartridge, but because it’s standard. The original Glocks were designed around the 9x19mm cartridge. With very few exceptions, weapons systems tend to work best in their original caliber. My first Glock was a 9mm, and as time went along I was more interested in the next one taking the same ammo as the previous ones, than I was in it being the “best” cartridge available. Debating the merits and shortcomings of the 9x19mm cartridge is beyond the scope of this article. Here’s why standardization is important, especially to me:

I tried to share ammo with a deputy from Cameron County once, during the “lull in the action” after a gunfight. We had one bad guy down (as were three good guys, one of whom was a good gal) but we still, allegedly, had two bad guys at large. The deputy was almost out of ammo, and–God be praised–we both had Berettas. I started to hand him my second spare mag, when we realized that his Beretta took 9mm, and mine shot .40.

Not having compatible ammo is NOT gonna happen in our house.

However, during the great ammo panic of the COVID-19 era, 9mm became hard to come by, so I have since expanded my options to a few different calibers, just in case of a future shortage. But I think of those as equivalent to the USAF’s old “Priority B” resources, only to be called up in times of disorder or emergency. Our “go-to” handguns remain nine millimeters.

Details of the Class A Mishap

In the Air Force, when an aircraft crashed and was completely destroyed, we called that a “Class A mishap.” I’m not sure if this mag falling apart qualifies. It’s only a Class A mishap if all the king’s horses & men can’t put Humpty back together. As every fourthclassman (freshman) at the Air Force Academy knows, a crash is defined as:

“A landing in which the vertical velocity is so great and the time spent reducing it to zero is so brief that the deceleration and hence the forces acting are so great as to cause structural failure.”

—Contrails, 1981 – 82 (Class of ’85) edition, p. 170

Initial examination of the magazine parts revealed no cracks or other significant damage. I’ve since reassembled it, and it will probably function just fine. But I’m relegating it to the practice mags, just the same. According to my notes it had been loaded on “Priority A Alert status” for nearly 5 years, since November of 2018, so it was probably time to replace it anyway.

I used to rotate out my carry ammo every quarter. I would shoot up my old carry loads during qualification, and then load fresh duty rounds. That slowed considerably half a decade ago when I retired and Uncle Sugar stopped giving me free ammo. In my defense, my carry ammo isn’t as exposed to the elements nearly as much these days. But I probably should get off my wallet a little more often with quality defensive ammo, which runs in excess of a dollar a cartridge these days.

Nothing made by man is indestructible. If that magazine had dropped out of an aircraft at altitude and reached terminal velocity, which is the fastest it can fall with wind resistance (let’s call it 300 feet per second or so, although it’s probably higher; magazines are narrow and dense–lead bullets are heavy–so they slip through the air pretty well), it would of course have practically exploded when it hit the ground. The cartridge primers might not have detonated, but the plastic and metal sheath holding the cartridges in spring-loaded tension would have busted apart and / or been bent beyond all repair.

In my case though, the magazine slipped off a shelf and fell just over four feet–48 and 7/8 inches–before striking the bottom “door sill” of a steel safe.

I didn’t see exactly how it hit the lip of the safe, or what part hit what at what angle of attack. I was looking away (I think the mag caught on my sleeve which pulled it off the edge of the shelf). There was no black box onboard for us to review the flight data. I know the base plate and the follower, which are on opposite sides of the magazine spring, both wound up back in the safe, behind some rifles. The body of the magazine, along with the 10 cartridges that were still in it, and the 5 that had spilled out, wound up on the ground outside the safe, along with the mag spring (which probably flew into the safe but then bounced back out), and the magazine insert.

The insert is a flat piece of plastic with a cylindrical nub that sticks down into a hole in the middle of the floor plate as added insurance to keep it from coming off, unless the operator WANTS it to come off, in which case she or he would push in on the nub / insert with a pin punch (see GTUL photo below). When they first came out, Glock magazines did not have the insert.

Wind resistance would be negligible over such a short drop. The acceleration of gravity is just over 32 feet per second per second (no, that’s not a typo; it’s also written “per second squared”). Don’t make the mistake of thinking I’m any sort of mathematician, much less a physicist. I loved Physics so much, I had to take it twice. But according to the Omni Freefall Calculator, the magazine fell for half a second, and was only traveling about 16 feet per second when it struck the steel lip of the safe.

I’m surprised that was enough to flex it apart.

Magazine RO5

The OEM Glock 17 magazine was marked RO5 on the butt plate. In my numbering scheme, that’s to indicate it was the 5th mag I got from Glock for working as Range Officer at Glock Sport Shooting Foundation matches.

It’s not critical to keep track of such esoterica, but if I know where I got it, it helps me to remember how long any given mag has been in service.

I normally carry a Glock 19 or a 26 with two spare Glock 17 magazines (see The Lie: How Much Ammo Do You Need? if you think that’s overkill). For some time now, RO4 and RO5 have been my two EDC spares.

RO5 recently got taken off-line and stuck in the safe till I could dig out another “duty” cartridge for it. I stole the top round out of RO5 to re-fill the chamber when I lost the original chambered round somewhere in my truck vault.

Although we were required to do it every day in the Air Force, it’s not a good idea to catch the round you are removing from the chamber of a pistol with a fixed ejector. If you bobble it and the primer strikes the tip of the ejector–BOOM! Unsupported by the chamber, the cartridge case will become a mini brass (or aluminum or steel or nickel plated brass) hand grenade. Never seen it happen myself, but I know a few different instructors who have witnessed it.

I dropped a bag of reloaded ammo once; the rim of one .357 hit the primer of another, and–Pop!–cartridges and frags of the one (thank God it was only one) that literally exploded flew from between my feet. The lead bullet of that cartridge was wedged into the cardboard of a box full of brass about 2 feet away (it wasn’t going very fast, as the rapidly conflagrating powder had not been channelized behind it in a barrel).

The fragments of a cartridge case that ruptures when the primer strikes the ejector will follow the two paths of least resistance:

- down the mag well, and

- out of the ejection port, into your palm.

So it’s a better idea to let the chambered round fly. At my truck vault, I roll the pistol right and let the ejected round fall onto a blanket in there (if you have only one piece of emergency equipment in your car, it should be a blanket).

I’m not one for constantly loading and clearing the chamber–it wears out your ammo, and any manipulation increases the chances of a negligent discharge, so the safest course is to avoid unnecessary manipulation.

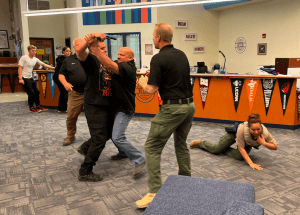

But I teach a lot of educators active shooter response, first aid, and such. When we do scenario training, I leave dangerous instrumentalities in the truck.

Technically, Arizona law says the gun must be unloaded when stored in a car on school property. If I can unload it surreptitiously (without causing a scene, or increased security risk from somebody seeing me store the gun in there), I do.

Sometimes when I do, the formerly chambered round falls down underneath some of the other gear in the truck vault. If I don’t feel like digging for it (or, again, if it would cause a scene) after class, I just rob from my second spare mag to get me home, and replace it later. I figure having the gun loaded correctly is more important than the second spare magazine having my standard load, since I would have to go through all the ammo in the gun and all the ammo in the first spare before getting down to the last round in the second spare.

Stranger things have happened. When we were crouched behind a Chevy Caprice, Cameron County Deputy Rodriguez (in photo by wreath above) looked at me and said “I’m down to two rounds.” He had started with 46, between the rounds in his Beretta and his two spare magazines. He’d run the gun (shot it) to slide lock, performed a reactive “emergency” reload, shot every round in that second mag, reloaded with his last mag, and was down to one round in the last magazine, plus one in the chamber.

Cut the guy some slack. The bad guy had a rifle, and was considerably farther away than the farthest distance that most agencies qualify at. Deputy Rodriguez had just seen two Border Patrol agents get gunned down before his eyes. The deputy standing to one side of him (also named Rodriguez; no relation) got shot through the lung. The partner to the other side of him also went down (that officer had been shot about 5 years before by a gang-banger in McAllen; he wasn’t about to stand in the open and duke it out with anybody, so he dove for cover). All Rodriguez saw was good guys falling all around him, and he was taking fire himself, so we can’t blame him for being in a hurry. It was in a very rural area, so there was little chance of collateral damage.

Deputy Rodriguez did note, however, that he went through his first two magazines as fast as he’d ever shot before, without really aiming. When he got about halfway through his second and last spare magazine, he started to get desperate, so he slowed down on the trigger and focused hard on the front sight. He noted an immediate difference downrange, as the murderer started getting hit with his shots.

Downloading One

As a general rule, I keep our “alert” mags charged (loaded) one short of capacity, for reliability. With many (not all) systems, loading the magazine to capacity increases the tension on the feed lips so much that the resultant friction makes that top round less likely to chamber on the first try. In short, with any magazine that holds more than 10 rounds or so,

“First round reliability is more important than last round capacity.”

. . . which is something I tell students. I learned it from Louis Awerbuck, though I don’t believe those were his exact words. He was not the only genuine expert to tell me that.

RO5, then, was down two rounds from maximum capacity when it dropped. The mag holds 17 rounds, I normally keep it loaded with 16, and it was short one from there that day. There were 15 rounds in it when it fell.

As I mentioned, I’d had that magazine loaded with duty ammo for nearly 5 years, since November of 2018. Since the spring that pushes the cartridges up also pushes down on the insert, which has one of the three nubs that hold the base plate in place, I suppose a worn spring could have contributed to the base plate popping off.

Mag RO5 is one of the later models. The body of the magazine has two notches for the magazine catch, in case one wishes to switch the mag release to left handed. It has a number 6 follower. The followers have been improved over the years, and number 6 is one of the most recent. I have a few with number 7 followers now.

I’ve heard sixes called “number 9” followers, but there is a dot or period next to the 6, like this: 6.

It’s not like this: 9.

I carefully function tested mag RO5 with a mix of duty and practice ammo, then put it on alert status and did not practice with it. It didn’t get dropped on the range deck a hundred times–or even once.

All of which is to say that, while RO5 was not brand new, was not an ancient, worn out hunk of polymer and steel that had been used and abused on the firing range.

Training Mags and Duty Mags

It’s a good idea to have two sets of magazines:

- Those you reserve for “alert” status (duty carry or standby in your home), and

- Practice mags you drop on the range floor, step on, kick around, practice clearing failures to extract (“double feeds”) with, etc.

That keeps your duty magazines in what Q would call “pristine working order.”

Function Checks

Test your duty magazines to make sure they will work with your chosen defensive ammo in your gun, when you first put them on “alert” status. You should probably function test them every once in a while after that, but be gentile with them and don’t wear them out. Don’t drop them in the dirt.

Duty ammo is expensive. One way you can test it with duty ammo without breaking the bank is to start loading duty ammo (say 2 or 3 rounds), then load practice ammo, then duty ammo (somewhere int he middle of the magazine), then practice ammo again, then top it off (the last two or three rounds) with duty ammo. If it works through all of that, you’re probably good to go for loading it with entirely duty ammo and leaving it alone.

My standard used to be “300 rounds without a hiccup” before I would trust a new gun or gear for it. Those days ended when I retired and stopped getting free ammo. But if you have the budget and the range time, it’s not a bad standard to bet your life on.

Label Them

It’s a good idea to mark your magazines in some way, like the tail numbers on different aircraft. That way, if one of your magazines consistently fails to feed or whatever, you know to relegate it to the training mags or get rid of it or at least do further research with that particular magazine to figure out what’s going on.

I mark mine in two different places, in case the number wears off in one location, but that’s probably overkill. I also orient the numbers differently for .40s than I do for 9mm magazines. The caliber of Glock OEM magazines is marked near the top on the back of the mag body, but my numbering system is a lot easier to see.

The Inevitable Federal 10 (7? 15?) Round Limit

You should get a new magazine every paycheck. They’re more durable than toilet paper but still expendable, like car batteries or tires. They will wear out eventually, just as eventually there will be another federal statute creating an arbitrary nation-wide mag capacity limit. When (not if) that happens, supplies of the original magazines will dry up quickly, and the value of your “grandfathered” standard capacity mags will go up exponentially.

This is not conjecture. We saw it happen before, right after the “Crime Bill” of the 1990s went into effect. I was a rookie cop in those days, grossing less than $1400 a month, when the price of magazines (standard duty gear I had to supply for myself) went from $12 for a new one to $84 for a used one. Most cops in most departments in America must supply their own gear, just as a nurse might not be issued a stethoscope by his or her hospital. Apart from mandatory sentencing guidelines (which worked a lot better to bring down crime that arbitrarily banning certain features of guns), the Crime Bill didn’t do cops any favors.

Police officers were still allowed to purchase standard capacity magazines during the Ban, but the process was involved and expensive. And while I don’t believe (as many Americans apparently do) that the life of a police officer is somehow worth less than that of other citizens, I don’t believe it’s worth more either. If a cop can defend herself or himself with a standard capacity 15 round magazine in a Glock 19–the kind it was designed for–why can’t John Q Public?

Floor / Base Plate Options

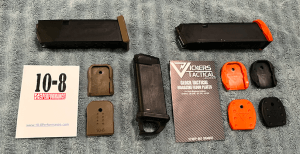

The floor plate of RO5 was the original one. There are several aftermarket floor plates out there that purport to be easier to pull out one handed or whatever. I have experimented with some of these. I used black Vickers floor plates on my duty Glock 17 when I served warrants; since I was not interested in concealing the pistol while we kicked doors (a figure of speech for serving warrants; one rarely actually kicked a door), the extra width of the Vickers floor plate was not a disadvantage.

Floor plates of not only a different color, but a different shape (that you can feel in the dark) might be useful to, say, differentiate between your .40 mags and your 9mm mags, if you have both in your collection, and both are deployable assets in a SHTF situation.

Another valid reason you might swap the base plates of your magazines might be to add an extension. The base plates above could be considered extensions in that they are thicker and wider than standard floor plates. But I’m talking here about something that adds significant length to your magazine.

Unless you have extremely narrow fingers, the baby Glocks only have enough grip for your middle and ring fingers to wrap around them. If you want your pinkie on there as well, you can use a magazine that essentially extends the grip.

Some grip extensions also extend your ammunition capacity. A word of caution about those: if you’ve kept, say, a 10 round Glock 26 magazine loaded to capacity for some time, then add a hollow base plate that holds two more rounds, it’s a good idea to get a new spring while you’re at it. The old spring may have taken a “set.” Perhaps surprisingly (unless something has changed since my last Glock armorer course), OEM Glock mags use the same springs, whether they have a flat floor plate or a +2 extension.

All of the above are legit motivations for swapping the base plates on your magazines. However, without a compelling reason (“the look” is probably not one), it’s NOT advisable to swap out the floor plates on your Glock.

For one thing, it’s hard to do. The rim on the bottom of the mag body has a trapezoidal nub on each side that keeps the plate from popping off easily. It’s really difficult, even when you are depressing the third, cylindrical nub on the magazine insert through the hole in the middle of the base plate and cranking the plate forward with your pin punch. That’s one reason why it surprised me that the base plate popped off by itself; it’s quite a chore to do it on purpose.

If the side nubs of mag RO5 had been worn down by constant removal of the plate, chasing fashion or just cleaning the mag, again, I could understand it. But that was not the case. The base plate of this magazine had never been removed.

Magazine maintenance is under-appreciated and often overlooked. With mags that are easier to disassemble, they are best cleaned from the bottom. But for fear or wearing out those side nubs that make the Glock OEM magazine so robust, I would clean yours from the top with a brush, while holding the magazine upside down.

Better yet, keep your duty mags for duty. Drop your practice mags in the dirt. I realize that for some–Border Patrol Agents, for example–the duty pistol itself rolls around in the dirt on a regular basis. But for most of us, we usually have a choice about which gear we keep pristine and which we get down and dirty with.

Aftermarket Magazines

A friend of mine carried Safariland speedloaders back in the revolver days. The Safarilands had the advantage of being easier to use one handed (yes, you CAN reload a revolver with only one hand) than their major competitor, HKS.

Once, while he was chasing a bad guy, one of his speedloader pouches came open. His plastic Safariland speedloader hit the ground and was later found to have spilled all its cartridges on impact. I don’t remember whether or not the speedloader was irreparably damaged, but as soon as he could he converted to HKS speedloaders, which were slightly more complicated to use (requiring an additional twisting of the metal knob while holding the cylinder with the other hand to keep it from rotating) but which were also more robust, and less likely to lose their cartridges if he dropped one during a hasty reload, while crouched behind a Crown Vic.

“Weapons should be hardy, rather than decorative.”

–Miyamoto Musashi, The Benefit of Weapons in Strategy, in A Book of Five Rings (Victor Harris trans), p. 48

Glock OEM magazines are about the most robust available.

How can I say that, when the central focus of this article is an OEM mag that came apart when dropped four feet?

The reason I felt compelled to write about it is because it was so very unusual.

I’ve dropped a lot of magazines in nearly 3 decades of daily experience with Glocks (mostly empty mags, during reactive reloads on the firing range). RO5 was the ONLY OEM Glock mag that came apart. Others, like the ProMags (see below), come apart on a regular basis.

There are more Glocks, and more aftermarket options for Glocks, than any other pistols in the US.

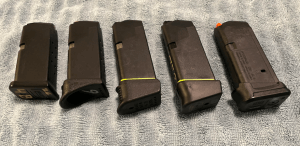

MagPul PMAG

AR and M4 operators agree that MagPul PMAGs are among the best AR magazines available.

MagPul PMAGs for Glock pistols are every bit as robust, and arguably more robust, than OEM Glock mags. Whether or not PMAGs are as reliable in feeding the chamber as OEMs is subject to debate.

PMAGS have some bonus features. One, which was subsequently stolen by Glock, was orange followers (the follower in you magazine is the “floor of the elevator” that pushes the rounds up so they can feed into your chamber). PMAGs are a little harder to load, and have fewer witness holes used to see how many rounds you have left (OEMs and KCIs give you an exact count).

I can’t prove this, but I’m nearly convinced that Glock was losing so much magazine market share to MagPul that they altered the interior dimensions of their Gen 5 pistols to make PMAGs less reliable in them.

I would consider PMAGs to be “Priority B resources” for my Glock pistols (which are Generations 2 – 4), although my good friend Dan G, who was a partner of mine in the Feds and whose opinion I respect, says he wouldn’t bet his life on one.

I use PMAGs for practice.

KCI

. . . is a Korean concern that makes reverse engineered clones of Glock (and other) magazines. I’ve fond them to be reliable but not quite as robust.

Interestingly, I tried to swap out the base plate that came with a KCI .40 Glock mag with a 10-8 base plate, and found the KCI to be affixed to the magazine with some sort of chemical (glue) or molding process. I got it done, but ended up ripping the thin, flimsy body of the mag. I have a few KCIs for practice, but would NOT bet my life on them.

Pro Mags

A friend who was disgusted with ProMags gave me a few, or should I say the parts to them.

ProMags have the benefit of being more affordable than the other after market options. But they are made out of fragile plastic and are famous for popping apart when they hit the ground, or even when seated firmly in the magazine well of a pistol. I certainly wouldn’t bet my life on them, if I had any choice.

I don’t even use ProMags for practice.

I keep ProMag bits (and the one that’s still in one piece) on hand as visual aids when teaching new gun owners how going cheap with life saving gear is usually false economy.

–George H, armorer

About the Author

or,

Why You Can Believe This

George H, lead instructor for Heloderm, is a five-time graduate of Glock Armorer courses, beginning in 1992.

He’s also a graduate of a week-long Beretta factory armorer’s course.

George was a certified field armorer for three different federal agencies. He attended Department of Justice field armorer training and enhanced field armorer certification programs, as well as Homeland Security field armorer training at the National Firearms and Tactical Training Unit.

George was a small arms armorer (glorified supply specialist) for a Field Artillery Battery when he wore Army green. Two of the years he was with the AZ ArNG, he was on active duty, assigned to a firing range full time, where part of his duties included repairing broken guns.

George was a small arms maintenance specialist (and firearms instructor) for the last 8 years he wore Air Force blue (actually BDUs, Deserts, and ABUs) as a Reservist (IMA) assigned to an active duty Security Forces squadron. He’s a graduate of the Combat Arms Training and Maintenance school, as well as upgrade training in that field.

Jim Fuller, then of Rifle Dynamics, trained George as a Kalashnikov armorer.

None of which makes George an engineer or a gunsmith, but it does mean he knows a little about magazines.